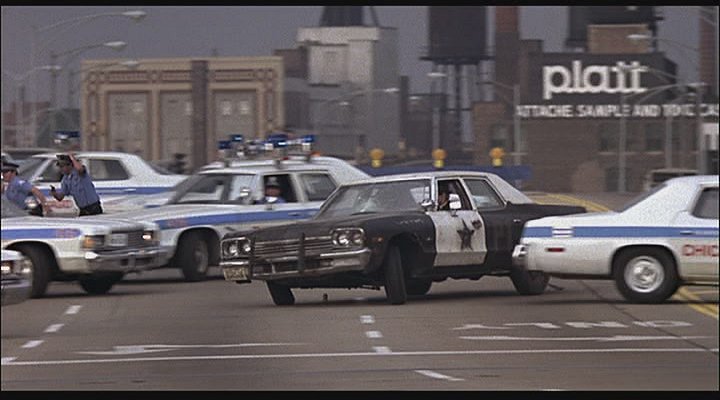

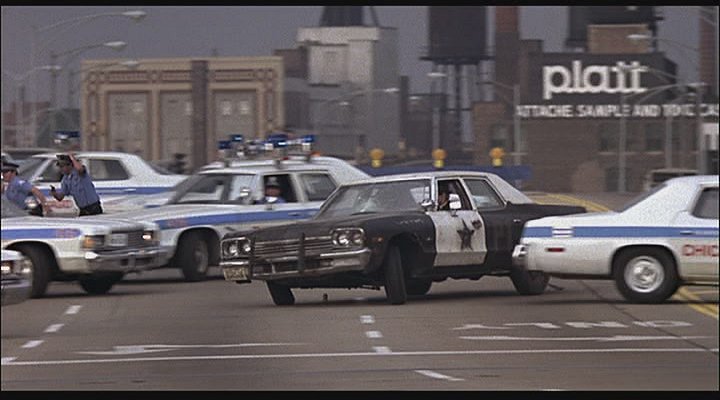

And people wonder why improved geometry and wheels are needed on these old cars?

Suspension plans:

The suspension has some issues when it

comes to cornering:

Reversed camber curve (Upper control arms angle down towards the wheel)

Bump steer (Toe out on bump)

Rollcenter (RC) heights (Front: Below ground. Rear: Above the differential)

Front RC migration (Just reduce, or hopefully minimize it)

Spring-/wheelrates (too soft/low)

Roll angle during cornering (Excessive body roll)

Rear converging 4 link (C4L) (Bind during travel/roll)

Rear roll-steer (Gains a lot of roll-understeer after lowering)

High polar moment of inertia (Slow response to steering commands)

Bushing compliance (Too soft)

And people wonder why improved geometry and wheels are needed on these old cars?

Thoughts/plans:

Before getting some

suspension software, I have some thoughts on what to start out with, and explore

some of the options I have. I'll start by mocking up the expected ride- and tire

height, to check the height difference between the inner and outer pivot points in

the lower control arms (LCAs). I have already bought HOWE 1/2" extended

lower balljoints (LBJs), and hope to avoid having the LCAs tilt down to the center of the

car at normal ride height. I want the front crossmember ~4" above ground

(roughly a 4" drop), combined with tires ~26" tall. This will

give me a rough baseline for how the geometry works out. Possible options for getting

the front RC height at ~2" above ground after the ride height is set, are tall upper

balljoints (UBJs), and moving around the upper control arm (UCA) mounts, which

stock are quite tall.

I'm not too worried about meeting this RC height goal as I am with RC migration, correcting the camber curve or the bump-steer. The

extended LBJs also help me meet my initial ride height goal, as they drop the chassis an equal

amount and help flip the front view instant center (FVIC) to the inside of the wheel. Initial

front view sving arm (FVSA)

length at ~80", but I need to know what the shortest "safe" length at full

bump

is, and may adjust it some. RC migration will be observed, and I hope it can be

made to be within acceptable values (atleast less than ~4" lateral). Lots of time will be spent playing with

the numbers here.

NOTE: This is nowhere near a project of designing a "perfect" suspension, I'm just trying to improve the stock crap within my capability and budget, without making the car any more unpredictable, or even downright dangerous to drive.

Front:

I want as wide as possible front track width

that will fit without flaring (mods to wheel lip and inner wheelwells are expected),

while keeping the scrub

radius as small as possible. This is a big task, and the shorter tires I'm

planning on using won't help. I already have solid

steel bushings for the UCAs, and the lightweight steel/nylon bushings for the

LCAs to take care of the slop in the stock rubber bushings. The steering arms on the spindles

are too low in stock form, creating bump-steer (toe out on bump travel). I hope the tall lower balljoints

can help minimize this, together with ~5-7 degrees of positive caster. If necessary, I'm prepared to

move around the steeringbox/idler some to lessen the bumpsteer. Perfect

isn't the goal here, just general improvement of the overall package. I hope I can

get as little toe-out as possible while not getting any toe-in, which should be

avoided. If moving the

steering box and idler is required, I'll examine how far back I can push the

centerlink and inner tierods before hitting the crossmember, or the tierods rub

the centerlink. ~1/2" looks possible, and a chance to

increase Ackermann is interesting. Removing the "hump"/horn at the front of the

frame may be needed for this. More Ackermann may not be needed at all, but it

should be considered. A quick-ratio steering box is

also badly needed, and a box from an '80's F-body fits my budget. There may be a need to tweak the internal steering stops, due to the long steering

arms on the spindles. The third picture shows the braces the rear LCA mounts got on the newer cars, I'll try and fabricate something similar on my frame,

only stronger. I'm also considering to tie the front framerails together,

distributing the load the steeringbox applies to the driverside rail, as well as

downbars from the cowl area of the firewall to the front framerails.

Rear:

![]()

After reading about a bolt-in 3-link

solution on the Pro-Touring.com forum, this approach got me interested. The

particular vehicle was a 1st gen A-body, but those cars have the same basic rear

suspension layout as the '73-96 B-body. My reasoning behind keeping a similar short

UCA length, is that it's a requirement for me that it bolts-in, and it can actually be made longer in side

view than the angled stockers are. It's not the

ideal length, but still it's an improvement from stock. The axle mount will be

fastened to the stock upper ears and half of the rear cover bolts (replaced

with stronger studs), and have 2-3 locating positions for altering the side view

instant center (SVIC) and

side view sving arm (SVSA). Making space for

suspension travel with the centered upper link may require raising the trunk

floor. As for the frame side bolt in bracket, a possible solution is a

~3/16" steel plate running from side to side between the stock upper mounts, fastened

both with the stock UCA bolts with some spacers to simulate bushings, and a

~3/16" steel plate on the other side of the frame - the steel plates bolted together, "sandwiching"

the frame. This is to spread the now centered load, and to help this further I'd

make some braces to tie the LCA and UCA mounts together similar to

Hotchkis' "Trailing arm braces", spreading the load. Lateral control of the rear

axle would be an as long as

possible, length adjustable, centered, and horizontal panhard bar with

height adjustable mounts. A good start is to replace the stock LCAs with rod

ends and tubing, and leave the stock UCAs and rubber bushings to help fight the

bind before a 3-link can be made.

Springs/bars:

![]()

I'll have to do a lot of

measuring/calculating/asking people before determining the front/rear

spring rates to go with as with everything else, currently estimating

~900/~250 lbs/in

depending on several factors.

I want a firm ride, driver comfort is not on the priority list right now.

For a

start the

stock thin swaybar at the front will be used, then try out other front/rear bar/no rear bar combinations

later. For the rear bar, a solution along the lines of the stock

3rd gen F-body rear bar, not mounted to the LCAs, may be used. Something adjustable

would also be a great bonus. The C4L is another problem,

as the built-in bind during travel and roll affects both the rear spring rate and roll stiffness, I'll

have to think about that one for a while (as in: dream about 3-link). The fact

that the bind is non-linear adds to the wish for removing the C4L bind. Another

problem is lowering the rear RC, needing more spring stiffness and roll resistance, again affecting the

rear springs/bars. Street-stock springs combined with adjustable spring shims will

be used in the front. In the rear, I have the option of "adjusting" the rear spring mounts

to make the rear ride/frame height match the front (the rear has double pigtail springs),

or the solution I really want - to use single pigtail springs and weight jacks accessible

through the trunk.

More on this will be posted sometime in the future...